Dear All,

Below is the WSH Alert (Case) on the collapsing of Concrete Test Block @ Gilstead Rd (Newton).

For you perusal.

Looking back at this accident, it’s proven (again) that the company fore-thought (started in mid 2010) of using welded-joined steel plates to replace the concrete test block has simply caught the attention of few parties, including authorities and potential clients.

Number of these similar initiatives significantly have improves the industry standard or, I would say, as part of the recognised Best Practices, the crème de la crème (best of best) of sustainable innovative above all.

And, the company always welcomes your idea/comment towards a better and safe mode of our operation.

Thank You and Have a Good weekend.

Regards,

David Simon.

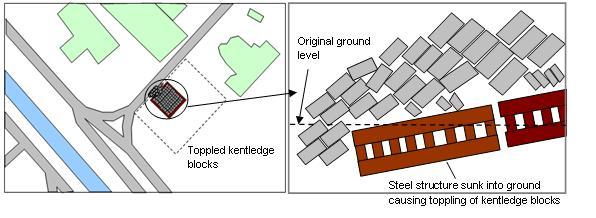

WSH Alert – Toppling of Kentledge Stack

Incident

On 16 Jan 2011, during a pile load test at a construction worksite, a structural frame supporting the kentledge structure sunk into the ground causing the concrete blocks to topple and fall. The blocks fell beyond the worksite and landed onto a public road. The incident resulted in road closure for several days in order for the blocks to be removed safely. No one was injured in the incident.

Recommendations*

1. Conduct proper foundation assessment: A Professional Engineer must carry out proper foundation assessment (i.e. bearing capacity checks on the foundation) prior to commencement of any pile load test.

2. Conduct risk assessment: Risk assessment in conducting the pile load test must cover the installation and the zone of possible collapse of the kentledge stack. Where the zone of possible collapse falls out of the worksite’s boundary, proper control measures must be taken to contain the collapse zone within the worksite. Where this cannot be achieved, reselection of the pile to be tested or alternative methods for pile load test (e.g. use of steel plates instead of concrete blocks, reaction pile method etc.) should be considered instead.

3. Implement proper safe work procedures: Safe work procedures for installation of kentledge system for pile load test must be implemented and include checks on critical items to be considered, from planning to erection of the kentledge system, conducting the test and reading of test results. Briefing(s) should be carried out to all personnel involved in the works and key areas of safe work procedures should be communicated to all workers on site.

4. Ensure safety of equipment / machinery used: Valid certification must be available for all lifting machines and lifting platforms, including piling machines, cranes etc. that are mobilized on site.

Further Information

1. Workplace Safety and Health Act (Chapter 354A).

2. Workplace Safety and Health (General Provisions) Regulations.

3. Workplace Safety and Health (Risk Management) Regulations.

4. Workplace Safety and Health (Construction) Regulations.

5. SS515: 2005 Supervision of Structural Works – Checklist 4 – Static pile load test using kentledge stack.

6. SS CP4: 2003 Singapore Standard on Code of Practice for Foundations

- Please note that the information provided is not exhaustive and for the benefit of enhancing workplace safety and health so that a recurrence may be prevented. The information provided is not to be construed as implying any liability to any party nor should it be taken to encapsulate all the responsibilities and obligations of the reader of WSH Alert under the law.

For your info on this accident.

- http://www.straitstimes.com/BreakingNews/Singapore/Story/STIStory_624992.html

- http://news.asiaone.com/News/AsiaOne%2BNews/Singapore/Story/A1Story20110117-258528.html

Video of the collapsing blocks: